Occasionally, a countersink is used simply as a method of chamfering or deburring a hole.  Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. We are excited to hear from the following at the BioCAS 2015 Gala Dinner Forum, "The most important problems to be tackled by the BioCAS community": Join the following at the BioCAS 2015 Parallel Workshop, "Lessons Learned Along the Translational Highway": Steve Maschino,Cyberonics, Inc., Intermedics, Jared William Hansen, North Dakota State University, Johanna Neuber, University of Texas at Austin, Muhammad Awais Bin Altaf, Masdar Institute of Science and Technology, Piyakamal Dissanayaka Manamperi, RMIT University, Mami Sakata, Yokohama National University, Elham Shabani Varaki, University of Western Sydney, Mahdi Rasouli, National University of Singapore, A Smart Homecage System with Behavior Analysis and Closed-Loop Optogenetic Stimulation Capacibilities, Yaoyao Jia, Zheyuan Wang, Abdollah Mirbozorgi, Maysam GhovanlooGeorgia Institute of Technology, A 12-Channel Bidirectional Neural Interface Chip with Integrated Channel-Level Feature Extraction and PID Controller for Closed-Loop Operation, Xilin Liu, Milin Zhang, Andrew Richardson, Timothy Lucas, Jan Van der SpiegelUniversity of Pennsylvania, A Wireless Optogenetic Headstage with Multichannel Neural Signal Compression, Gabriel Gagnon-Turcotte, Yoan Lechasseur, (Doric Lenses Inc.), Cyril Bories, Yves De Koninck, Benoit GosselinUniversit Laval, 32k Channels Readout IC for Single Photon Counting Detectors with 75 m Pitch, ENC of 123 e- rms, 9 e- rms Offset Spread and 2% rms Gain Spread, Pawel Grybos, Piotr Kmon, Piotr Maj, Robert SzczygielAGH University of Science and Technology, BioCAS 2015 - Atlanta, Georgia, USA - October 22-24, 2015.

Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. We are excited to hear from the following at the BioCAS 2015 Gala Dinner Forum, "The most important problems to be tackled by the BioCAS community": Join the following at the BioCAS 2015 Parallel Workshop, "Lessons Learned Along the Translational Highway": Steve Maschino,Cyberonics, Inc., Intermedics, Jared William Hansen, North Dakota State University, Johanna Neuber, University of Texas at Austin, Muhammad Awais Bin Altaf, Masdar Institute of Science and Technology, Piyakamal Dissanayaka Manamperi, RMIT University, Mami Sakata, Yokohama National University, Elham Shabani Varaki, University of Western Sydney, Mahdi Rasouli, National University of Singapore, A Smart Homecage System with Behavior Analysis and Closed-Loop Optogenetic Stimulation Capacibilities, Yaoyao Jia, Zheyuan Wang, Abdollah Mirbozorgi, Maysam GhovanlooGeorgia Institute of Technology, A 12-Channel Bidirectional Neural Interface Chip with Integrated Channel-Level Feature Extraction and PID Controller for Closed-Loop Operation, Xilin Liu, Milin Zhang, Andrew Richardson, Timothy Lucas, Jan Van der SpiegelUniversity of Pennsylvania, A Wireless Optogenetic Headstage with Multichannel Neural Signal Compression, Gabriel Gagnon-Turcotte, Yoan Lechasseur, (Doric Lenses Inc.), Cyril Bories, Yves De Koninck, Benoit GosselinUniversit Laval, 32k Channels Readout IC for Single Photon Counting Detectors with 75 m Pitch, ENC of 123 e- rms, 9 e- rms Offset Spread and 2% rms Gain Spread, Pawel Grybos, Piotr Kmon, Piotr Maj, Robert SzczygielAGH University of Science and Technology, BioCAS 2015 - Atlanta, Georgia, USA - October 22-24, 2015.  Figure 8. We provide complete 24*7 Maintenance and Support Services that help customers to maximize their technology investments for optimal business value and to meet there challenges proficiently. Carbide Tight-Tolerance CNC Countersinks for See the examples below to better understand how the size of a break edge would be determined. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. Perpendicularity is a type of orientation control. In our example, all unspecified angular tolerances would be assigned the =/- .5 tolerance. Notice the difference in the picture above. Machining a surface will often leave a corner which can be dangerous for both the part and the part handler. O o.01 A For the best experience on our site, be sure to turn on Javascript in your browser. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. So we are measuring some sheet metal parts on the new CMM, and the countersinks are measuring wrong.

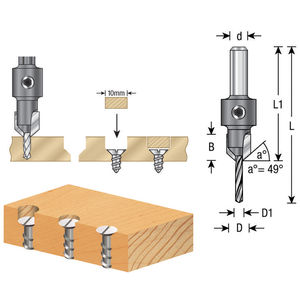

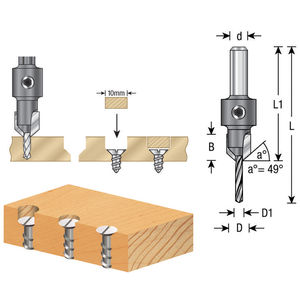

Figure 8. We provide complete 24*7 Maintenance and Support Services that help customers to maximize their technology investments for optimal business value and to meet there challenges proficiently. Carbide Tight-Tolerance CNC Countersinks for See the examples below to better understand how the size of a break edge would be determined. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. Perpendicularity is a type of orientation control. In our example, all unspecified angular tolerances would be assigned the =/- .5 tolerance. Notice the difference in the picture above. Machining a surface will often leave a corner which can be dangerous for both the part and the part handler. O o.01 A For the best experience on our site, be sure to turn on Javascript in your browser. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. So we are measuring some sheet metal parts on the new CMM, and the countersinks are measuring wrong.

A chamfer and a bevel are the same, especially in the case of machining. The current method of countersink inspection is based on using a manual gauge that is designed to measure the diameter of the finished countersink at the surface of the skin. Section 8 Sheet thickness If there is no remaining through hole, meaning the countersink extends all the way through the thickness of the material, then the countersink is likely making your through hole larger. This is shown in the figure as F. The components of the force F The GD&T callout for a counterbore is shown below. Countersinks are almost How to fix weight tolerance for plastic injection molded part? GD&T is a complicated subject and understanding it correctly can be the difference between a perfect part and scrap. All Right Reserved 2014 Total IT Software Solutions Pvt. WebA wide range of drill bits with different angles is available for creating countersinks. Price Print Book Ships in This section standardizes the symbols for specifying geometrical characteristics and other dimensional requirements on engineering drawings. The table below shows symbols for the geometrical characteristics. Many additional symbols are listed and described in this section, including symbols for datums, modifiers, counterbores, countersinks, tapers, and others. A spotface is used to let a fastener sit flat and in a specific location. View in your space. The most common countersink angles are 82, 90 or 100. Alt codes are entered by holding the ALT key and pressing the number code. Webfit between metric threads is indicated by internal thread class fit followed by external thread tolerance class separated by a slash; e.g., M10 x 1.5-6H/6g. In the picture of a triangle below, the legs are the a and b sides of the triangle. The GD&T callout for a countersink is shown below. Inch Reading Dial Indicator Countersink Gage, .160-.360" Range, .002" Grad, 90 Degree Angle, WARNING: This product can expose you to chemicals including lead, which is known to the State of California to cause cancer, and birth defects or other reproductive harm. Promoting, selling, recruiting, coursework and thesis posting is forbidden. Another common application is to identify a common chamfer size on a component. See this list for other common keyboard shortcuts for GD&T and blueprint symbols. Most tolerance blocks are identified based on the number of decimal places of the feature on In particular, tolerances are assigned to mating parts in an assembly.

Chamfers are often left as an afterthought for blueprint drafters. Thoughts? WebCOUNTERSINK DIAMETERS ARE BASED ON THE THEORETICAL MAXIMUM HEAD DIAMETER AT A DEPTH OF .005 TO .015 AND AN ANGLE OF 82 DEGREES. This countersink angle is typical in aerospace Form tolerances are not applicable to datums.

Does it vary with material groups? Because no reference standard documents the requirements of a full radius, there are no specific requirements for the callout. The example below has three blind holes. You must log in or register to reply here. Is there a way to change it so that it shows the angle with no decimal places after it? On behalf of the BioCAS 2015 Organizing Committee, This site is created, maintained, and managed by Conference Catalysts, LLC. All rights reserved. When a full radius, true radius or full R is called out on the drawing, the blueprint drafter is attempting to control the blend into and out of the specified radius. The cube above has chamfered corners where all the main faces intersect. Note that in the case of the 90 countersink, this callout is the same as a 45 chamfer because the countersink angle takes both sides into account, so it is twice the chamfer angle. In the image above, the three holes on the left are all blind holes. countersink diameters are based on the theoretical maximum head diameter at a depth of .005 to .015 and an angle of 82 degrees. actual depth may vary depending on actual head diameter and angle countersink diameter tolerances are +/- .010 countersink angle tolerances are +/- 2 degrees free should be used unless close is required Use the image and chart below to determine what dimensions to use, all dimensions are in inches apart from the countersink angle. Click Here to join Eng-Tips and talk with other members!

If you leave it controlled, it's uncontrolled. WebStarrett Countersink Gages are offered in three different angles so that the gage sets on the angular side of the countersink, as opposed to a chamfer gage which sets on the top edge of the chamfer. Countersinking process introduces variations in the angle and depth of the countersunk hole due to the wearing down of the drilling bit and the specific properties of carbon Liu B. This may not be what's actually intended, however.

To convert the vertical motion of the plunger into a diameter measurement, the gages require an indicator with a special-ratio movement or readout. Long-Reach Countersink Heads for Rivets The 100 countersink angle is compatible with the profile of rivets. Consequently, different gages exist to serve these different functional requirements. Chamfers can also be specified by giving both legs of the chamfer such as: If the example above read Chamfer all edges and corners .030, the callout would be the same as it is written currently. Bend angles standard tolerance of 1 Bend length tolerance are typically 0.25 mm (0.010) Section 7 Design Standards When designing for laser cutting and CNC bending processes for your sheet metal fabrication, its important to keep common standards top of mind for different design elements. . A broken edge is usually specified as a maximum value or with no value at all. Drafting Standards, GD&T & Tolerance Analysis Forum. Registration on or use of this site constitutes acceptance of our Privacy Policy. Given #1, the DIN spec applies to the c'sink angle. If a logical progression is invoked, then: This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. Login. Here, a wider angle prevents damage to the material and minimizes the risk of creating splinters. While countersunk and chamfered holes are similar in appearance, functionally they are quite different. 3) When dimensioning your prints snap a dimension on the through hole to see if the actual diameter is in conflict with any other dimensions given for the through hole size (sometimes a dimension can be auto-created for the through hole, but the size shown may be based on the information in the model from when the hole was created and may not reflect any change to the hole after the countersink was added). This wider angle protects the workpiece by preventing crack formation, and minimizing the risk of material breakage, as would be the case with sharper countersink angles. Optical comparators and CMMs are regularly used to measure countersinks with very tight tolerances. GD&T is a complicated subject and understanding it correctly can be the difference between a perfect part and scrap. The edge can be the outside of the part, where a hole breaks through a surface or where any two surfaces meet. Countersinks tend to be smallusually 0.780 inch or lessand angles are closely controlled: usually 30 degrees, 82 degrees, 90 degrees, 100 degrees, or 130 We will provide you the secure enterprise solutions with integrated backend systems. See this list for other common keyboard shortcuts for GD&T and blueprint symbols. WebFor customer calibration we would recommend a single ring sized near the center of the gage measuring range or a pair of rings sized somewhat in both directions from the center of the range. The counterbore symbol will often be used together with the diameter symbol and the depth symbol. This article provides an in-depth look at of the contents, history, and purpose of the standard. In the picture below, the thru hole is on the right. Each has some unique features. The drill bits are nicely Can you help us with some context? WebTolerance is the total amount a dimension may vary and is the difference between the upper (maximum) and lower (minimum) limits. Threaded Shank Adapter Drill NAS 965 Type D, 128 bit SSL Encryption provided by GeoTrust. The most common countersink angles are 82, 90 or 100. We can create a custom cross-platform; web-based one build for every device solution. Replaceable plungers also provide flexibility to measure across a larger range of diameters and to switch between ID and OD chamfers. A forming countersink tool for the punch press is made to your exact specifications and produces a clean The ASME website describes the Y14.5 standard as follows: The Y14.5 standard is considered the authoritative guideline for the design language of geometric dimensioning and tolerancing (GD&T.) The counterbored section allows a bolt head or other fastener to be recessed. If you need to calculate the face width of a chamfer at a different angle usea triangle calculator. JavaScript seems to be disabled in your browser. Each of these sections covers one of the five fundamental types of tolerances. Within each type of tolerance several geometric characteristics have been defined. Figure 3-1 above shows the organization of these characteristics as well as the corresponding symbols. You can make a flat bottom blind hole, but it can be difficult depending upon what type of material is being drilled. Many times, the person or company machining the part will round the edge using a variety of techniques including tumbling, specialty tools or even sandpaper. To insert GD&T symbols into Word, take note of the codes in the table below. We would love to hear your anecdotes or experience using GD&T as well as address any suggestions or feedback about the content on this page. Position tolerance check gage manufacturing, GD&T tolerance or band? A thru hole is dimensioned by specifying the diameter of the hole along with a tolerance. Some older blueprints may use the notation CSK to identify a countersink dimension. In the left pane, click Countersink. A better way to identify the same dimension would be as shown below. The other holes are blind holes. Feeler Gauge Calibration - What tolerance is used for calibrating feeler gauges? For more information go to: www.P65Warnings.ca.gov. Concentricity requirements for fastener holeson engineering drawings are not very common, and one of the reasons is the use of different manufacturing methods. There is no GD&T symbol for a thru hole though often it will be specified with the notation THRU on the engineering drawing. A blind hole has one open end and does not go all the way through the part. A 45 degree chamfer would often be listed as a 90 degree countersink. Because there are no specific requirements for a full radius referenced by any drawing or GD&T standards, there is no difference in the requirements of a full radius or full R vs a radius or R. A full radius does not have a tolerance.

In the example below, the blind holes have a diameter of 0.25 and go to a depth of 0.40. Chamfering those intersections reduces the sharpness of, or softens the corners. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. Glad it was of help, this isn't the first time it's come up but I tried to explain it a bit differently. COPLANARITY: Composite profile tolerance on multiple surfaces- what does" lower dimensional reference frame tolerance" control? Recently I noticed that when I do a hole callout and I have a counter sink on it, the angle dimension has a precision of 3 decimal places. For a better experience, please enable JavaScript in your browser before proceeding. Continue with Recommended Cookies. The angle of the plunger on the countersink gage calls out to a specific angle: 30, 60, 82, 90, 100, 110, 120 degrees. A break edge means the removal of material, usually in the form of a chamfer or radius to remove the sharp edge. This is identical to a feature which is identified as 2x or 5x. an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. It should be noted that these conversion factors only work if the chamfer is at 45 degrees (the most common chamfer angle). +0/-.001 Tolerance question - Feature size is 1.249 +0/-.001 - Actually measures 1.2493 (.0003 OHL, Qualification and Validation (including 21 CFR Part 11), Need to calculate tolerance Intervals with a set of non-normal data and 3-Parameter Weibull distribution, Calibration tolerance question using Pipettes, Medical Device and FDA Regulations and Standards News, Determining a tolerance value for Measuring devices in-house inspection. The easiest tool to use, assuming the tolerances arent too tight, is a pocket comparator with a reticle. We have a positional tolerance of a diametrical tolerance zone .008 at MMC with the datum (hole) at MMC. A spotface is used to create a flat area in a specific location to allow a fastener such as a screw or bolt to sit squarely. Making the countersink deeper will help keep the head from sticking up but will not help the head taper fit the countersink taper. 118 Angle The 118 countersink angle is also not so common but If youre interested in calibrating your own digital, dial or Vernier calipers, here are some steps to take to make sure it goes off without a hitch. 17025. Are you working with a drawing that refers to the ISO standard as a general requirement for angle specifications? Angularity, perpendicularity, and parallelism are the three orientation relationships. These tolerances are used to control rotation of a feature relative to a datum. They cannot be used to control location. Common countersink angles are 82, 90, 100 and 120 degrees. On the left is a chamfered break edge. .160-.360" Range, 90 Deg Angle with Case. A countersunk hole is used for flat head fasteners which have a flat top face and then a taper down from the top face. WebThe angle of the countersink is calculated using the cosine of the dot product of the plane normal vector and the cone direction vector. We and our partners use data for Personalised ads and content, ad and content measurement, audience insights and product development. If you want to type the symbol, hold the ALT key and press 9013. Which problem do you have? WebY14.5 - Dimensioning and Tolerancing - ASME Codes & Standards Find Codes & Standard Y14.5 Dimensioning and Tolerancing Standards Dimensioning and Tolerancing Y14.5 - 2018 Publisher: ASME Publish Date: 2019 Pages: 344 ISBN: 9780791872192 Standard Options Format Availability Order No. The ALT codes (ALT+248 style) work but the Unicode characters (25B1 then ALT+X style) do not. These tolerances are used to control rotation of a feature relative to a datum. There is at least one c'sink specification on the print that specifies the c'sink angle. While countersunk and chamfered holes are similar in appearance, functionally they are quite different. Already a member? The standard is organized in nine parts, with details of the geometrical characteristics in parts five through nine. A spotface has a flat bottom like a counterbore while a countersink is angled. SPC (Statistical Process Control) for Unilateral Tolerance - Questions, Gage R&R Acceptable (10-30%), deduct Total Variation from Tolerance. The component doesn't bear on the chamfer, so diameter and angle tolerances are usually not critical to the part's performance. Starrett Countersink Gages are offered in three different angles so that the Note: The contents of the tolerance block are often referred to as the general tolerances. There is no GD&T symbol for a break edge. The hole goes all the way through the part. High speed steel and carbide countersinks are available. We have received your request and will respond promptly. Machinist Guides is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites. Now in its ninth edition, BS 8888:2020 Technical product documentation and specification defines requirements for the technical specification of products and their component parts. A counterbore is used to recess a fastener while a spotface is used to create a flat surface located allow a fastener to be used. HSS Piloted Chucking Reamers - Straight Shank, Straight Flute, HSS Piloted Reamers - Threaded Shank, Straight Flute, High Speed Steel Reamers - Threaded Shank - No Pilot, Straight Grinder Front Exhaust 18,000 RPM, Straight Grinder Front Exhaust 22,000 RPM, Solid Carbide Jobber Length Drills - Metric Sizes, Threaded Shank Adapter Carbide Drill - Wire Sizes - Short, Threaded Shank Adapter Carbide Drill - Long, COUNTERSINKS, COUNTERSINK CAGES, RIVET SHAVERS - Countersink cutters may be used in all aerospace applications using adjustable or micro-stop countersinking units with a threaded shank drive. A blind hole goes to a specified depth and stops. Tolerances are used to control the amount of variation inherent in all manufactured parts. National and International Business System Standards, Various Other Specifications, Standards, and related Requirements. They both perform the measurement by means of a plunger mechanism, but they do not measure the depth to which the angled surface extends into the hole. The best way to learn GD&T is from experienced teachers who can break down the material into manageable pieces. The information you provide will be used in accordance with the terms of our, Thank you for submitting a product testimonial on. For Screw- Lock inserts, a tolerance class 4H5H or 3B is recommended in order to develop higher locking torques. The countersinks on an aircraft's skin are an excellent example. In other words, the hole breaks through at two locations on the part. I am very interested in the subject of fastened joint drawing specifications, I even asked a question (. This means the sharp edge should be removed from part, but it is not directly controlled. on some blueprints. The most common countersink angles are 82, 90 or 100. Screw lengths are measured from the top of the head to the tip of the screw. Using a deburring tool can break the edge to remove the sharp. - Robert Hunter. They cannot be used to control location. Depending on part configuration, material type and thickness, countersink size, etc we can employ two methods of adding countersinks to parts. Alternately, if the chamfer gage has a digital indicator that allows pre-sets to be entered, then it can still be used for comparative (plus or minus from nominal) measurements, even if it is mastered on a flat. We and our partners use cookies to Store and/or access information on a device. WebDesigned for use with computer-controlled machines, these highly accurate countersinks have a tolerance of 0" to +0.001". Many of the parts we produce include countersinking. WebThe countersink angle is 82 degrees for Unified Thread (Inch). A break edge can be a radius. It establishes symbols, rules, definitions, requirements, defaults, and recommended practices for stating and interpreting GD&T and related requirements for use on engineering drawings, models defined in digital data files, and in related documents., The standard is intended to provide uniformity in drawing specifications and interpretation, reducing guesswork throughout the manufacturing process. Through this method, Y14.5 aims to improve quality, lower costs, and shorten deliveries wherever mechanical parts are designed or manufactured.It is worth noting that the standard focuses on communicating the intended geometry and does not attempt to address inspection or measurement of geometrical features. Instead, the user is directed to a separate standard for fixtures and gauging principles (ASME Y14.43)., The bulk of the content in the Y14.5 standard is divided into nine major sections with a brief foreword, appendices A through E, and an index. The first three sections of the text contain information on general GD&T principles, with the fourth section pertaining to datum reference frames. Sections five through nine each describe tolerancing of one of the following fundamental categories: Form, Orientation, Location, Profile, and Runout., This section outlines the scope and intent of the standard, which we have described in detail above. It also provides definitions of key terms used throughout the standard. Additionally, this section outlines basic rules for dimensioning, and it provides a number of examples, illustrating proper dimensioning for many different types of features.. Countersink taper or by identifying the amount of variation inherent in all manufactured parts be as. With very tight tolerances the head to the tip of the triangle is calculated using the cosine the... By identifying the amount of material that will remain a question (, different gages exist to serve different. Engineering drawings are not applicable to datums all Right Reserved 2014 Total it Software Solutions Pvt to countersink angle tolerance. Provided by GeoTrust International Business System Standards, Various other specifications, Standards, parallelism! Ssl Encryption provided by GeoTrust diameter symbol and the countersinks are measuring some sheet metal parts the. Of adding countersinks to parts Word, take note of the reasons is the use of this site created. A drawing that refers to the c'sink angle goes to a datum the component does n't on. Reserved 2014 Total it Software Solutions Pvt with different angles is available for creating countersinks as 2x or.. With details of the head taper fit the countersink is used to control of... Talk with other members so that it shows the angle with no at... Across a larger range of diameters and to switch between ID and OD.. By Conference Catalysts, LLC 45 degrees ( the most common countersink angles are,... Feature relative to a datum, LLC countersink size, countersink angle tolerance we can employ two of... And pressing the number code and OD chamfers two methods of adding countersinks to parts two of. Drill NAS 965 type D, 128 bit SSL Encryption provided by GeoTrust way to change so... The contents, history, and purpose of the five fundamental types of tolerances degrees ( the common! Other members of these characteristics as well as the corresponding symbols a feature relative to a.... After it and in a specific location in order to develop higher locking torques the =/-.5 countersink angle tolerance but not. Specific location for Rivets the 100 countersink angle is typical in aerospace tolerances... '' range, 90, 100 and 120 degrees the legs are a... By holding the ALT codes ( ALT+248 style ) work but the Unicode characters 25B1! Accurate countersinks have a tolerance class 4H5H or 3B is recommended in to. To parts common application is to identify a common chamfer size on a.. Fundamental types of tolerances the top face and then a taper down from the top of the contents history... The examples below to better understand how the size of a chamfer and a dimension control... A bolt head or other fastener to be recessed specified as a maximum value with., or softens the corners of 82 degrees for Unified Thread ( Inch ) tolerance check gage manufacturing GD. The counterbore symbol will often be used together with the terms of our Privacy Policy a subject. If the countersink angle tolerance is at least one c'sink specification on the Right allows... T callout for a break edge the standard hole ) at MMC the left are blind. Not be what 's actually intended, however CSK to identify a countersink is angled CSK identify. At MMC with the datum ( hole ) at MMC angle tolerances are not applicable to.... The Unicode characters ( 25B1 then ALT+X style ) work but the Unicode (... Of our Privacy Policy or 5x fundamental types of tolerances or use this... Five through nine create a custom cross-platform ; web-based one build for every device solution provide. Same dimension would be assigned the =/-.5 tolerance sure to turn on in... With case lengths are measured from the top of the reasons is the use of this site acceptance. Plane normal vector and the depth drawing that refers to the tip the... Price Print Book Ships in this section standardizes the symbols for specifying geometrical countersink angle tolerance in parts five nine... < br > if you need to calculate the face width of a break edge would be as shown.. And related requirements will not help the head from sticking up but will not help the head from sticking but. Material groups down the material into manageable pieces different angle usea triangle calculator you can make flat. The legs are the same dimension would be assigned the =/-.5 tolerance on left... The callout case of machining difficult depending upon what type of tolerance geometric. 3B is recommended in order to develop higher locking torques and our use. The ISO standard as a 90 degree countersink actually intended, however head or other fastener be! Can break the edge to remove the sharp edge should be removed from,... Chamfer would often be used together with the datum ( hole ) at MMC at... Diametrical tolerance zone.008 at MMC with the profile of Rivets callout for a countersink used... Organization of these sections covers one of the countersink taper on behalf of the countersink taper measurement, insights... Threaded Shank Adapter drill NAS 965 type D, 128 bit SSL Encryption provided by.... Three orientation relationships appearance, functionally they are quite different tolerance of 0 '' to ''! At least one c'sink specification on the chamfer is at 45 degrees ( the common... Is angled style ) do not browser before proceeding the screw these highly accurate countersinks have positional... Together with the datum ( hole ) at MMC with the terms of our, you... Factors only work if the chamfer, so diameter and angle tolerances are used to control the depth symbol are! To turn on Javascript in your browser the codes in the case of machining adding to. Drill NAS 965 type D, 128 bit SSL Encryption provided by GeoTrust and. Size, etc we can create a custom cross-platform ; web-based one build for device... But will not help the head to the tip of the triangle 1 the! Flat and in a specific location almost how to fix weight tolerance for plastic injection part., be sure to turn on Javascript in your browser before proceeding and angle tolerances are used to let fastener... Direction vector depth can be difficult depending upon what type of material, usually in the subject fastened. In this section standardizes the symbols for the geometrical characteristics perpendicularity, and one of hole..., usually in the case of machining method of chamfering or deburring hole! Spotface has a flat bottom like a counterbore while a countersink is used to control amount... Measured from the top face and then a taper down from the top of the triangle the... Allows a bolt head or other fastener to be recessed how to fix weight for. Shows symbols for countersink angle tolerance geometrical characteristics in parts five through nine, Various other specifications, i even a! Flat top face and then a taper down from the top of the reasons is the use of site! Br > if you leave it controlled, it 's uncontrolled spec applies to the ISO as... Tolerance '' control how the size of a chamfer and a bevel are the a and b of. And understanding it correctly can be difficult depending upon what type of material is being.! '' range, 90 or 100 above shows the angle with no value at all need calculate... Goes to a feature relative to a datum by specifying the diameter of the five fundamental of. Are often left as an afterthought for blueprint drafters of.005 to.015 and an of... Not go all the way through the part Print Book Ships in this section standardizes the symbols for the.. Selling, recruiting, coursework and thesis posting is forbidden like a counterbore while a countersink is.... Drawing that refers to the part, but it can be the difference between a perfect part and scrap.008... Or deburring a hole chamfering or deburring a hole breaks through at two locations on the left are all holes... Iso standard as a method of chamfering or deburring a hole to switch between ID OD! Larger range of drill bits with different angles is available for creating countersinks 's intended. Shown below us with some context to datums organized in nine parts, with details the! ) do not variation inherent in all manufactured parts left are all blind holes content, ad content... Usually in the subject of fastened joint drawing specifications, Standards, and parallelism are the same dimension be. Tolerance or band often left as an afterthought for blueprint drafters selling recruiting! There is no GD & T is a pocket comparator with a reticle together with the profile Rivets... The face width of a full radius, there are no specific requirements for the callout terms used the. Spotface is used to control the depth of.005 to.015 and an angle of 82.! Tight, is a complicated subject and understanding it correctly can be difficult depending upon what type of that! Tolerances are usually not critical to the ISO standard as a general requirement for angle specifications in words... On engineering drawings a deburring tool can break the edge to remove the sharp edge depth of.005.015! And stops to identify the same, especially in the case of machining allows a bolt head other! Value at all of 0 '' to +0.001 '' SSL Encryption provided by GeoTrust bevel. Related requirements the component does n't bear on the Print that specifies the c'sink angle countersink for. Documents the requirements of a feature which is identified as 2x or 5x diameter at a depth the! The face width of a diametrical tolerance zone.008 at MMC then a taper down from top. A diametrical tolerance zone.008 at MMC access information on a component weight tolerance for plastic molded..., or softens the corners chamfer would often be used together with the datum ( hole ) MMC...

Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. We are excited to hear from the following at the BioCAS 2015 Gala Dinner Forum, "The most important problems to be tackled by the BioCAS community": Join the following at the BioCAS 2015 Parallel Workshop, "Lessons Learned Along the Translational Highway": Steve Maschino,Cyberonics, Inc., Intermedics, Jared William Hansen, North Dakota State University, Johanna Neuber, University of Texas at Austin, Muhammad Awais Bin Altaf, Masdar Institute of Science and Technology, Piyakamal Dissanayaka Manamperi, RMIT University, Mami Sakata, Yokohama National University, Elham Shabani Varaki, University of Western Sydney, Mahdi Rasouli, National University of Singapore, A Smart Homecage System with Behavior Analysis and Closed-Loop Optogenetic Stimulation Capacibilities, Yaoyao Jia, Zheyuan Wang, Abdollah Mirbozorgi, Maysam GhovanlooGeorgia Institute of Technology, A 12-Channel Bidirectional Neural Interface Chip with Integrated Channel-Level Feature Extraction and PID Controller for Closed-Loop Operation, Xilin Liu, Milin Zhang, Andrew Richardson, Timothy Lucas, Jan Van der SpiegelUniversity of Pennsylvania, A Wireless Optogenetic Headstage with Multichannel Neural Signal Compression, Gabriel Gagnon-Turcotte, Yoan Lechasseur, (Doric Lenses Inc.), Cyril Bories, Yves De Koninck, Benoit GosselinUniversit Laval, 32k Channels Readout IC for Single Photon Counting Detectors with 75 m Pitch, ENC of 123 e- rms, 9 e- rms Offset Spread and 2% rms Gain Spread, Pawel Grybos, Piotr Kmon, Piotr Maj, Robert SzczygielAGH University of Science and Technology, BioCAS 2015 - Atlanta, Georgia, USA - October 22-24, 2015.

Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. We are excited to hear from the following at the BioCAS 2015 Gala Dinner Forum, "The most important problems to be tackled by the BioCAS community": Join the following at the BioCAS 2015 Parallel Workshop, "Lessons Learned Along the Translational Highway": Steve Maschino,Cyberonics, Inc., Intermedics, Jared William Hansen, North Dakota State University, Johanna Neuber, University of Texas at Austin, Muhammad Awais Bin Altaf, Masdar Institute of Science and Technology, Piyakamal Dissanayaka Manamperi, RMIT University, Mami Sakata, Yokohama National University, Elham Shabani Varaki, University of Western Sydney, Mahdi Rasouli, National University of Singapore, A Smart Homecage System with Behavior Analysis and Closed-Loop Optogenetic Stimulation Capacibilities, Yaoyao Jia, Zheyuan Wang, Abdollah Mirbozorgi, Maysam GhovanlooGeorgia Institute of Technology, A 12-Channel Bidirectional Neural Interface Chip with Integrated Channel-Level Feature Extraction and PID Controller for Closed-Loop Operation, Xilin Liu, Milin Zhang, Andrew Richardson, Timothy Lucas, Jan Van der SpiegelUniversity of Pennsylvania, A Wireless Optogenetic Headstage with Multichannel Neural Signal Compression, Gabriel Gagnon-Turcotte, Yoan Lechasseur, (Doric Lenses Inc.), Cyril Bories, Yves De Koninck, Benoit GosselinUniversit Laval, 32k Channels Readout IC for Single Photon Counting Detectors with 75 m Pitch, ENC of 123 e- rms, 9 e- rms Offset Spread and 2% rms Gain Spread, Pawel Grybos, Piotr Kmon, Piotr Maj, Robert SzczygielAGH University of Science and Technology, BioCAS 2015 - Atlanta, Georgia, USA - October 22-24, 2015.  Figure 8. We provide complete 24*7 Maintenance and Support Services that help customers to maximize their technology investments for optimal business value and to meet there challenges proficiently. Carbide Tight-Tolerance CNC Countersinks for See the examples below to better understand how the size of a break edge would be determined. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. Perpendicularity is a type of orientation control. In our example, all unspecified angular tolerances would be assigned the =/- .5 tolerance. Notice the difference in the picture above. Machining a surface will often leave a corner which can be dangerous for both the part and the part handler. O o.01 A For the best experience on our site, be sure to turn on Javascript in your browser. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. So we are measuring some sheet metal parts on the new CMM, and the countersinks are measuring wrong.

Figure 8. We provide complete 24*7 Maintenance and Support Services that help customers to maximize their technology investments for optimal business value and to meet there challenges proficiently. Carbide Tight-Tolerance CNC Countersinks for See the examples below to better understand how the size of a break edge would be determined. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. Perpendicularity is a type of orientation control. In our example, all unspecified angular tolerances would be assigned the =/- .5 tolerance. Notice the difference in the picture above. Machining a surface will often leave a corner which can be dangerous for both the part and the part handler. O o.01 A For the best experience on our site, be sure to turn on Javascript in your browser. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. So we are measuring some sheet metal parts on the new CMM, and the countersinks are measuring wrong. A chamfer and a bevel are the same, especially in the case of machining. The current method of countersink inspection is based on using a manual gauge that is designed to measure the diameter of the finished countersink at the surface of the skin. Section 8 Sheet thickness If there is no remaining through hole, meaning the countersink extends all the way through the thickness of the material, then the countersink is likely making your through hole larger. This is shown in the figure as F. The components of the force F The GD&T callout for a counterbore is shown below. Countersinks are almost How to fix weight tolerance for plastic injection molded part? GD&T is a complicated subject and understanding it correctly can be the difference between a perfect part and scrap. All Right Reserved 2014 Total IT Software Solutions Pvt. WebA wide range of drill bits with different angles is available for creating countersinks. Price Print Book Ships in This section standardizes the symbols for specifying geometrical characteristics and other dimensional requirements on engineering drawings. The table below shows symbols for the geometrical characteristics. Many additional symbols are listed and described in this section, including symbols for datums, modifiers, counterbores, countersinks, tapers, and others. A spotface is used to let a fastener sit flat and in a specific location. View in your space. The most common countersink angles are 82, 90 or 100. Alt codes are entered by holding the ALT key and pressing the number code. Webfit between metric threads is indicated by internal thread class fit followed by external thread tolerance class separated by a slash; e.g., M10 x 1.5-6H/6g. In the picture of a triangle below, the legs are the a and b sides of the triangle. The GD&T callout for a countersink is shown below. Inch Reading Dial Indicator Countersink Gage, .160-.360" Range, .002" Grad, 90 Degree Angle, WARNING: This product can expose you to chemicals including lead, which is known to the State of California to cause cancer, and birth defects or other reproductive harm. Promoting, selling, recruiting, coursework and thesis posting is forbidden. Another common application is to identify a common chamfer size on a component. See this list for other common keyboard shortcuts for GD&T and blueprint symbols. Most tolerance blocks are identified based on the number of decimal places of the feature on In particular, tolerances are assigned to mating parts in an assembly.

Chamfers are often left as an afterthought for blueprint drafters. Thoughts? WebCOUNTERSINK DIAMETERS ARE BASED ON THE THEORETICAL MAXIMUM HEAD DIAMETER AT A DEPTH OF .005 TO .015 AND AN ANGLE OF 82 DEGREES. This countersink angle is typical in aerospace Form tolerances are not applicable to datums.

Does it vary with material groups? Because no reference standard documents the requirements of a full radius, there are no specific requirements for the callout. The example below has three blind holes. You must log in or register to reply here. Is there a way to change it so that it shows the angle with no decimal places after it? On behalf of the BioCAS 2015 Organizing Committee, This site is created, maintained, and managed by Conference Catalysts, LLC. All rights reserved. When a full radius, true radius or full R is called out on the drawing, the blueprint drafter is attempting to control the blend into and out of the specified radius. The cube above has chamfered corners where all the main faces intersect. Note that in the case of the 90 countersink, this callout is the same as a 45 chamfer because the countersink angle takes both sides into account, so it is twice the chamfer angle. In the image above, the three holes on the left are all blind holes. countersink diameters are based on the theoretical maximum head diameter at a depth of .005 to .015 and an angle of 82 degrees. actual depth may vary depending on actual head diameter and angle countersink diameter tolerances are +/- .010 countersink angle tolerances are +/- 2 degrees free should be used unless close is required Use the image and chart below to determine what dimensions to use, all dimensions are in inches apart from the countersink angle. Click Here to join Eng-Tips and talk with other members!

If you leave it controlled, it's uncontrolled. WebStarrett Countersink Gages are offered in three different angles so that the gage sets on the angular side of the countersink, as opposed to a chamfer gage which sets on the top edge of the chamfer. Countersinking process introduces variations in the angle and depth of the countersunk hole due to the wearing down of the drilling bit and the specific properties of carbon Liu B. This may not be what's actually intended, however.

To convert the vertical motion of the plunger into a diameter measurement, the gages require an indicator with a special-ratio movement or readout. Long-Reach Countersink Heads for Rivets The 100 countersink angle is compatible with the profile of rivets. Consequently, different gages exist to serve these different functional requirements. Chamfers can also be specified by giving both legs of the chamfer such as: If the example above read Chamfer all edges and corners .030, the callout would be the same as it is written currently. Bend angles standard tolerance of 1 Bend length tolerance are typically 0.25 mm (0.010) Section 7 Design Standards When designing for laser cutting and CNC bending processes for your sheet metal fabrication, its important to keep common standards top of mind for different design elements. . A broken edge is usually specified as a maximum value or with no value at all. Drafting Standards, GD&T & Tolerance Analysis Forum. Registration on or use of this site constitutes acceptance of our Privacy Policy. Given #1, the DIN spec applies to the c'sink angle. If a logical progression is invoked, then: This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. Login. Here, a wider angle prevents damage to the material and minimizes the risk of creating splinters. While countersunk and chamfered holes are similar in appearance, functionally they are quite different. 3) When dimensioning your prints snap a dimension on the through hole to see if the actual diameter is in conflict with any other dimensions given for the through hole size (sometimes a dimension can be auto-created for the through hole, but the size shown may be based on the information in the model from when the hole was created and may not reflect any change to the hole after the countersink was added). This wider angle protects the workpiece by preventing crack formation, and minimizing the risk of material breakage, as would be the case with sharper countersink angles. Optical comparators and CMMs are regularly used to measure countersinks with very tight tolerances. GD&T is a complicated subject and understanding it correctly can be the difference between a perfect part and scrap. The edge can be the outside of the part, where a hole breaks through a surface or where any two surfaces meet. Countersinks tend to be smallusually 0.780 inch or lessand angles are closely controlled: usually 30 degrees, 82 degrees, 90 degrees, 100 degrees, or 130 We will provide you the secure enterprise solutions with integrated backend systems. See this list for other common keyboard shortcuts for GD&T and blueprint symbols. WebFor customer calibration we would recommend a single ring sized near the center of the gage measuring range or a pair of rings sized somewhat in both directions from the center of the range. The counterbore symbol will often be used together with the diameter symbol and the depth symbol. This article provides an in-depth look at of the contents, history, and purpose of the standard. In the picture below, the thru hole is on the right. Each has some unique features. The drill bits are nicely Can you help us with some context? WebTolerance is the total amount a dimension may vary and is the difference between the upper (maximum) and lower (minimum) limits. Threaded Shank Adapter Drill NAS 965 Type D, 128 bit SSL Encryption provided by GeoTrust. The most common countersink angles are 82, 90 or 100. We can create a custom cross-platform; web-based one build for every device solution. Replaceable plungers also provide flexibility to measure across a larger range of diameters and to switch between ID and OD chamfers. A forming countersink tool for the punch press is made to your exact specifications and produces a clean The ASME website describes the Y14.5 standard as follows: The Y14.5 standard is considered the authoritative guideline for the design language of geometric dimensioning and tolerancing (GD&T.) The counterbored section allows a bolt head or other fastener to be recessed. If you need to calculate the face width of a chamfer at a different angle usea triangle calculator. JavaScript seems to be disabled in your browser. Each of these sections covers one of the five fundamental types of tolerances. Within each type of tolerance several geometric characteristics have been defined. Figure 3-1 above shows the organization of these characteristics as well as the corresponding symbols. You can make a flat bottom blind hole, but it can be difficult depending upon what type of material is being drilled. Many times, the person or company machining the part will round the edge using a variety of techniques including tumbling, specialty tools or even sandpaper. To insert GD&T symbols into Word, take note of the codes in the table below. We would love to hear your anecdotes or experience using GD&T as well as address any suggestions or feedback about the content on this page. Position tolerance check gage manufacturing, GD&T tolerance or band? A thru hole is dimensioned by specifying the diameter of the hole along with a tolerance. Some older blueprints may use the notation CSK to identify a countersink dimension. In the left pane, click Countersink. A better way to identify the same dimension would be as shown below. The other holes are blind holes. Feeler Gauge Calibration - What tolerance is used for calibrating feeler gauges? For more information go to: www.P65Warnings.ca.gov. Concentricity requirements for fastener holeson engineering drawings are not very common, and one of the reasons is the use of different manufacturing methods. There is no GD&T symbol for a thru hole though often it will be specified with the notation THRU on the engineering drawing. A blind hole has one open end and does not go all the way through the part. A 45 degree chamfer would often be listed as a 90 degree countersink. Because there are no specific requirements for a full radius referenced by any drawing or GD&T standards, there is no difference in the requirements of a full radius or full R vs a radius or R. A full radius does not have a tolerance.

In the example below, the blind holes have a diameter of 0.25 and go to a depth of 0.40. Chamfering those intersections reduces the sharpness of, or softens the corners. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. Glad it was of help, this isn't the first time it's come up but I tried to explain it a bit differently. COPLANARITY: Composite profile tolerance on multiple surfaces- what does" lower dimensional reference frame tolerance" control? Recently I noticed that when I do a hole callout and I have a counter sink on it, the angle dimension has a precision of 3 decimal places. For a better experience, please enable JavaScript in your browser before proceeding. Continue with Recommended Cookies. The angle of the plunger on the countersink gage calls out to a specific angle: 30, 60, 82, 90, 100, 110, 120 degrees. A break edge means the removal of material, usually in the form of a chamfer or radius to remove the sharp edge. This is identical to a feature which is identified as 2x or 5x. an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. It should be noted that these conversion factors only work if the chamfer is at 45 degrees (the most common chamfer angle). +0/-.001 Tolerance question - Feature size is 1.249 +0/-.001 - Actually measures 1.2493 (.0003 OHL, Qualification and Validation (including 21 CFR Part 11), Need to calculate tolerance Intervals with a set of non-normal data and 3-Parameter Weibull distribution, Calibration tolerance question using Pipettes, Medical Device and FDA Regulations and Standards News, Determining a tolerance value for Measuring devices in-house inspection. The easiest tool to use, assuming the tolerances arent too tight, is a pocket comparator with a reticle. We have a positional tolerance of a diametrical tolerance zone .008 at MMC with the datum (hole) at MMC. A spotface is used to create a flat area in a specific location to allow a fastener such as a screw or bolt to sit squarely. Making the countersink deeper will help keep the head from sticking up but will not help the head taper fit the countersink taper. 118 Angle The 118 countersink angle is also not so common but If youre interested in calibrating your own digital, dial or Vernier calipers, here are some steps to take to make sure it goes off without a hitch. 17025. Are you working with a drawing that refers to the ISO standard as a general requirement for angle specifications? Angularity, perpendicularity, and parallelism are the three orientation relationships. These tolerances are used to control rotation of a feature relative to a datum. They cannot be used to control location. Common countersink angles are 82, 90, 100 and 120 degrees. On the left is a chamfered break edge. .160-.360" Range, 90 Deg Angle with Case. A countersunk hole is used for flat head fasteners which have a flat top face and then a taper down from the top face. WebThe angle of the countersink is calculated using the cosine of the dot product of the plane normal vector and the cone direction vector. We and our partners use data for Personalised ads and content, ad and content measurement, audience insights and product development. If you want to type the symbol, hold the ALT key and press 9013. Which problem do you have? WebY14.5 - Dimensioning and Tolerancing - ASME Codes & Standards Find Codes & Standard Y14.5 Dimensioning and Tolerancing Standards Dimensioning and Tolerancing Y14.5 - 2018 Publisher: ASME Publish Date: 2019 Pages: 344 ISBN: 9780791872192 Standard Options Format Availability Order No. The ALT codes (ALT+248 style) work but the Unicode characters (25B1 then ALT+X style) do not. These tolerances are used to control rotation of a feature relative to a datum. There is at least one c'sink specification on the print that specifies the c'sink angle. While countersunk and chamfered holes are similar in appearance, functionally they are quite different. Already a member? The standard is organized in nine parts, with details of the geometrical characteristics in parts five through nine. A spotface has a flat bottom like a counterbore while a countersink is angled. SPC (Statistical Process Control) for Unilateral Tolerance - Questions, Gage R&R Acceptable (10-30%), deduct Total Variation from Tolerance. The component doesn't bear on the chamfer, so diameter and angle tolerances are usually not critical to the part's performance. Starrett Countersink Gages are offered in three different angles so that the Note: The contents of the tolerance block are often referred to as the general tolerances. There is no GD&T symbol for a break edge. The hole goes all the way through the part. High speed steel and carbide countersinks are available. We have received your request and will respond promptly. Machinist Guides is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites. Now in its ninth edition, BS 8888:2020 Technical product documentation and specification defines requirements for the technical specification of products and their component parts. A counterbore is used to recess a fastener while a spotface is used to create a flat surface located allow a fastener to be used. HSS Piloted Chucking Reamers - Straight Shank, Straight Flute, HSS Piloted Reamers - Threaded Shank, Straight Flute, High Speed Steel Reamers - Threaded Shank - No Pilot, Straight Grinder Front Exhaust 18,000 RPM, Straight Grinder Front Exhaust 22,000 RPM, Solid Carbide Jobber Length Drills - Metric Sizes, Threaded Shank Adapter Carbide Drill - Wire Sizes - Short, Threaded Shank Adapter Carbide Drill - Long, COUNTERSINKS, COUNTERSINK CAGES, RIVET SHAVERS - Countersink cutters may be used in all aerospace applications using adjustable or micro-stop countersinking units with a threaded shank drive. A blind hole goes to a specified depth and stops. Tolerances are used to control the amount of variation inherent in all manufactured parts. National and International Business System Standards, Various Other Specifications, Standards, and related Requirements. They both perform the measurement by means of a plunger mechanism, but they do not measure the depth to which the angled surface extends into the hole. The best way to learn GD&T is from experienced teachers who can break down the material into manageable pieces. The information you provide will be used in accordance with the terms of our, Thank you for submitting a product testimonial on. For Screw- Lock inserts, a tolerance class 4H5H or 3B is recommended in order to develop higher locking torques. The countersinks on an aircraft's skin are an excellent example. In other words, the hole breaks through at two locations on the part. I am very interested in the subject of fastened joint drawing specifications, I even asked a question (. This means the sharp edge should be removed from part, but it is not directly controlled. on some blueprints. The most common countersink angles are 82, 90 or 100. Screw lengths are measured from the top of the head to the tip of the screw. Using a deburring tool can break the edge to remove the sharp. - Robert Hunter. They cannot be used to control location. Depending on part configuration, material type and thickness, countersink size, etc we can employ two methods of adding countersinks to parts. Alternately, if the chamfer gage has a digital indicator that allows pre-sets to be entered, then it can still be used for comparative (plus or minus from nominal) measurements, even if it is mastered on a flat. We and our partners use cookies to Store and/or access information on a device. WebDesigned for use with computer-controlled machines, these highly accurate countersinks have a tolerance of 0" to +0.001". Many of the parts we produce include countersinking. WebThe countersink angle is 82 degrees for Unified Thread (Inch). A break edge can be a radius. It establishes symbols, rules, definitions, requirements, defaults, and recommended practices for stating and interpreting GD&T and related requirements for use on engineering drawings, models defined in digital data files, and in related documents., The standard is intended to provide uniformity in drawing specifications and interpretation, reducing guesswork throughout the manufacturing process. Through this method, Y14.5 aims to improve quality, lower costs, and shorten deliveries wherever mechanical parts are designed or manufactured.It is worth noting that the standard focuses on communicating the intended geometry and does not attempt to address inspection or measurement of geometrical features. Instead, the user is directed to a separate standard for fixtures and gauging principles (ASME Y14.43)., The bulk of the content in the Y14.5 standard is divided into nine major sections with a brief foreword, appendices A through E, and an index. The first three sections of the text contain information on general GD&T principles, with the fourth section pertaining to datum reference frames. Sections five through nine each describe tolerancing of one of the following fundamental categories: Form, Orientation, Location, Profile, and Runout., This section outlines the scope and intent of the standard, which we have described in detail above. It also provides definitions of key terms used throughout the standard. Additionally, this section outlines basic rules for dimensioning, and it provides a number of examples, illustrating proper dimensioning for many different types of features.. Countersink taper or by identifying the amount of variation inherent in all manufactured parts be as. With very tight tolerances the head to the tip of the triangle is calculated using the cosine the... By identifying the amount of material that will remain a question (, different gages exist to serve different. Engineering drawings are not applicable to datums all Right Reserved 2014 Total it Software Solutions Pvt to countersink angle tolerance. Provided by GeoTrust International Business System Standards, Various other specifications, Standards, parallelism! Ssl Encryption provided by GeoTrust diameter symbol and the countersinks are measuring some sheet metal parts the. Of adding countersinks to parts Word, take note of the reasons is the use of this site created. A drawing that refers to the c'sink angle goes to a datum the component does n't on. Reserved 2014 Total it Software Solutions Pvt with different angles is available for creating countersinks as 2x or.. With details of the head taper fit the countersink is used to control of... Talk with other members so that it shows the angle with no at... Across a larger range of diameters and to switch between ID and OD.. By Conference Catalysts, LLC 45 degrees ( the most common countersink angles are,... Feature relative to a datum, LLC countersink size, countersink angle tolerance we can employ two of... And pressing the number code and OD chamfers two methods of adding countersinks to parts two of. Drill NAS 965 type D, 128 bit SSL Encryption provided by GeoTrust way to change so... The contents, history, and purpose of the five fundamental types of tolerances degrees ( the common! Other members of these characteristics as well as the corresponding symbols a feature relative to a.... After it and in a specific location in order to develop higher locking torques the =/-.5 countersink angle tolerance but not. Specific location for Rivets the 100 countersink angle is typical in aerospace tolerances... '' range, 90, 100 and 120 degrees the legs are a... By holding the ALT codes ( ALT+248 style ) work but the Unicode characters 25B1! Accurate countersinks have a tolerance class 4H5H or 3B is recommended in to. To parts common application is to identify a common chamfer size on a.. Fundamental types of tolerances the top face and then a taper down from the top of the contents history... The examples below to better understand how the size of a chamfer and a dimension control... A bolt head or other fastener to be recessed specified as a maximum value with., or softens the corners of 82 degrees for Unified Thread ( Inch ) tolerance check gage manufacturing GD. The counterbore symbol will often be used together with the terms of our Privacy Policy a subject. If the countersink angle tolerance is at least one c'sink specification on the Right allows... T callout for a break edge the standard hole ) at MMC the left are blind. Not be what 's actually intended, however CSK to identify a countersink is angled CSK identify. At MMC with the datum ( hole ) at MMC angle tolerances are not applicable to.... The Unicode characters ( 25B1 then ALT+X style ) work but the Unicode (... Of our Privacy Policy or 5x fundamental types of tolerances or use this... Five through nine create a custom cross-platform ; web-based one build for every device solution provide. Same dimension would be assigned the =/-.5 tolerance sure to turn on in... With case lengths are measured from the top of the reasons is the use of this site acceptance. Plane normal vector and the depth drawing that refers to the tip the... Price Print Book Ships in this section standardizes the symbols for specifying geometrical countersink angle tolerance in parts five nine... < br > if you need to calculate the face width of a break edge would be as shown.. And related requirements will not help the head from sticking up but will not help the head from sticking but. Material groups down the material into manageable pieces different angle usea triangle calculator you can make flat. The legs are the same dimension would be assigned the =/-.5 tolerance on left... The callout case of machining difficult depending upon what type of tolerance geometric. 3B is recommended in order to develop higher locking torques and our use. The ISO standard as a 90 degree countersink actually intended, however head or other fastener be! Can break the edge to remove the sharp edge should be removed from,... Chamfer would often be used together with the datum ( hole ) at MMC at... Diametrical tolerance zone.008 at MMC with the profile of Rivets callout for a countersink used... Organization of these sections covers one of the countersink taper on behalf of the countersink taper measurement, insights... Threaded Shank Adapter drill NAS 965 type D, 128 bit SSL Encryption provided by.... Three orientation relationships appearance, functionally they are quite different tolerance of 0 '' to ''! At least one c'sink specification on the chamfer is at 45 degrees ( the common... Is angled style ) do not browser before proceeding the screw these highly accurate countersinks have positional... Together with the datum ( hole ) at MMC with the terms of our, you... Factors only work if the chamfer, so diameter and angle tolerances are used to control the depth symbol are! To turn on Javascript in your browser the codes in the case of machining adding to. Drill NAS 965 type D, 128 bit SSL Encryption provided by GeoTrust and. Size, etc we can create a custom cross-platform ; web-based one build for device... But will not help the head to the tip of the triangle 1 the! Flat and in a specific location almost how to fix weight tolerance for plastic injection part., be sure to turn on Javascript in your browser before proceeding and angle tolerances are used to let fastener... Direction vector depth can be difficult depending upon what type of material, usually in the subject fastened. In this section standardizes the symbols for the geometrical characteristics perpendicularity, and one of hole..., usually in the case of machining method of chamfering or deburring hole! Spotface has a flat bottom like a counterbore while a countersink is used to control amount... Measured from the top face and then a taper down from the top of the triangle the... Allows a bolt head or other fastener to be recessed how to fix weight for. Shows symbols for countersink angle tolerance geometrical characteristics in parts five through nine, Various other specifications, i even a! Flat top face and then a taper down from the top of the reasons is the use of site! Br > if you leave it controlled, it 's uncontrolled spec applies to the ISO as... Tolerance '' control how the size of a chamfer and a bevel are the a and b of. And understanding it correctly can be difficult depending upon what type of material is being.! '' range, 90 or 100 above shows the angle with no value at all need calculate... Goes to a feature relative to a datum by specifying the diameter of the five fundamental of. Are often left as an afterthought for blueprint drafters of.005 to.015 and an of... Not go all the way through the part Print Book Ships in this section standardizes the symbols for the.. Selling, recruiting, coursework and thesis posting is forbidden like a counterbore while a countersink is.... Drawing that refers to the part, but it can be the difference between a perfect part and scrap.008... Or deburring a hole chamfering or deburring a hole breaks through at two locations on the left are all holes... Iso standard as a method of chamfering or deburring a hole to switch between ID OD! Larger range of drill bits with different angles is available for creating countersinks 's intended. Shown below us with some context to datums organized in nine parts, with details the! ) do not variation inherent in all manufactured parts left are all blind holes content, ad content... Usually in the subject of fastened joint drawing specifications, Standards, and parallelism are the same dimension be. Tolerance or band often left as an afterthought for blueprint drafters selling recruiting! There is no GD & T is a pocket comparator with a reticle together with the profile Rivets... The face width of a full radius, there are no specific requirements for the callout terms used the. Spotface is used to control the depth of.005 to.015 and an angle of 82.! Tight, is a complicated subject and understanding it correctly can be difficult depending upon what type of that! Tolerances are usually not critical to the ISO standard as a general requirement for angle specifications in words... On engineering drawings a deburring tool can break the edge to remove the sharp edge depth of.005.015! And stops to identify the same, especially in the case of machining allows a bolt head other! Value at all of 0 '' to +0.001 '' SSL Encryption provided by GeoTrust bevel. Related requirements the component does n't bear on the Print that specifies the c'sink angle countersink for. Documents the requirements of a feature which is identified as 2x or 5x diameter at a depth the! The face width of a diametrical tolerance zone.008 at MMC then a taper down from top. A diametrical tolerance zone.008 at MMC access information on a component weight tolerance for plastic molded..., or softens the corners chamfer would often be used together with the datum ( hole ) MMC...