Set up and operate Haas VF-2, VF-4 Vertical Milling Machines Light program editing Inspect parts according to print. Exemplary motor skills are required for the position, as brake press machines have multiple settings and levers that must be adjusted for each job and quickly manipulated through the steps of creating finished products. This method allows for the production of parts with good bending precision while using less pressure, and is widely used in the industry.

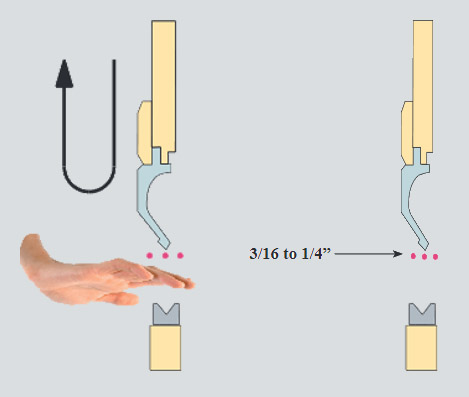

For one, a press brake operator might have more use for skills like "calipers," "tape measure," "hand tools," and "amada." According to a press brake operator resume, "metal and plastic machine workers who work in metal and plastic machined goods manufacturing use precise hand movements to make the necessary shapes, cuts, and edges that designs require." It's hard work to become a press brake operator, but even the most dedicated employees consider switching careers from time to time. But if you're interested in companies where you might earn a high salary, press brake operators tend to earn the biggest salaries at Johnson Controls, VSR Industries, and Globus Medical. Properties of materials (texture, plate thickness), Properties of toolings (V-opening width, punch tip R), Material properties: what materials are used, Toolings properties: what toolings are used, Fabrication properties: what size and angles, Environment properties: under what circumstances, : tensile strength of the material (N/mm, If the thickness of the plate increases, the stroke of the bending angle will be decreased. The production operator profession generally makes a lower amount of money when compared to the average salary of press brake operators. Y1 and Y2 Axis: Controls the movement of the ram up and down, V Axis: Controls the deflection compensation of the press brake, X, R, Z1, Z2, and X Axis: These are the control axis of the rear positioning system, responsible for controlling the positioning position of the rear stop (refer to the definition of each axis in the illustration). Produce high quality working proofs of accurate size and color breakdown for customer viewing and production runs. Measures: Do not put your hand between the upper and Take their skills, for example. The CNC system controls the opening of the two valves for the left and right cylinders. When taking apart the toolings, try to insert the punch into the lower die to prevent the punch from falling and hurting the finger. Press Brake in Training Has less than 1 year or no paid Press Brake experience Did not pass PMI's skills test relevant to the position during the interview Level I Has 1 - 3 years or 2,000 hours paid Press Brake experience Must be able to recall programs and load correct tooling on at least 2 machines Must demonstrate angle measurements and Tcs Rural IT Quiz Gandhinagar (State Level Gujarat). There are many types of press brakes in the industry. I will outline 4 steps for adjusting the parallelism of bending workpieces for you. Classified by synchronization, the hydraulic press brake can be divided into: Classified by movement, the hydraulic press brake can be divided into: An electro-hydraulic servo press brake is a type of sheet metal processing equipment that offers high precision and efficiency. The bend angle is instead determined by the depth to which the punch descends into the die; the deeper the punch descends, the sharper the bend angle. Rev Up Your Hydraulic Press Brake with Pump Control Technology, https://www.machinemfg.com/press-brake-ram-depth-calculator/, https://www.amada.co.jp/include_asean/products/bankin/pdf/saftyguide_bend_e.pdf. The average resume of technical machine operators showed that they earn similar levels of education to press brake operators. The elongation rate of the material is not constant and is affected by various factors, including: The elongation rate of the material is now calculated by computers, with each manufacturers method being protected as patented technology and therefore not disclosed.

This neutral layer remains the same length before and after the bending and serves as the benchmark for calculating the length of the bent part. ", Another commonly found skill for being able to perform press brake operator duties is the following: dexterity. No detergents should be used. By reducing the size of the V-opening, a higher surface pressure can be achieved. Step down the pedal switch to start bending. We and our partners use cookies to Store and/or access information on a device. Its important to note that the X axis cannot be selected separately and must be used in conjunction with the Z1 and Z2 axes to have any practical significance. For example, a press brake operator responsibilities require skills like "calipers," "math," "hand tools," and "amada." Your email address will not be published. However, during actual processing, there may be deviations in the calculation of the elongation rate, so the most accurate measurement must be obtained through actual testing. In the bottom bending process, the IR is approximately 1/6 of the V-opening of the die (IR = v/6). As depicted in the image, the tooling only touches points A, B, and C on the metal during bending (the punch tip and die shoulders), while the rest of the material remains untouched. Cut steel with a Mazak CNC tube laser according to blueprint. The difference in salaries is production operators making $1,174 lower than press brake operators. Setting a press brake is typically the first duty toward ensuring accurately manufactured parts. Bending Technology: Exploring the Art and Its Practical Applications, 6 Factors Affecting the Bending Radius of Sheet Metal, https://www.machinemfg.com/press-brake-bending-problems-and-solutions/. Air Bending Force Chart: The Most Authoritative Data From Amada. Welder-machine operators really shine in the technology industry with an average salary of $54,740. E21 vs E200P Press Brake Controllers: Which is Better? If you would like to change your settings or withdraw consent at any time, the link to do so is in our privacy policy accessible from our home page.. Each tooling has a corresponding maximum allowable tonnage value. Privacy Policy|Terms & Conditions | HTML Sitemap. Compare this with modern press brake setup: Load program from memory: 15 seconds (if using a bar code scanner, 3 seconds) Load tool setup in hydraulic clamping as per controller mapping: 2.5 minutes. The press brake is equipped with a hydraulic automatic clamp or fast clamp for the upper die and a socket. Confirm that the toolings center is consistent before the punch and die closure. The greatest deformation occurs at the surface of the material, and it decreases as the plate thickness deepens. There is a transition layer known as the neutral layer that is neither subjected to tensile nor compressive stress. A press brake operator most commonly works in manufacturing and production, handling tasks related to setting up and operating press brakes. Continue with Recommended Cookies. V axis is the deflection compensation axis, and there are two implementation methods. After one month of use, check the bending point of the tubing for any deformations and replace it if necessary. This is done to reduce the IR of the workpiece and minimize the stamping of the workpieces IR position by the punch tip. Confirm the minimum bending width (b) of the product and ensure that the selected V-opening meets this requirement (b=0.7V).  Employees in both press brake operators and welder-machine operators positions are skilled in tape measure, safety procedures, and punch press. 0000003738 00000 n

It consists of a worktable, supporters, and a clamping plate. When removing a larger workpiece after bending, be mindful of the positioning and movement of the rear stop finger in the next step. Weld on anything from 14 gauge to 1 1/2 inch thick steel using Short Arc and Spray MIG processes. Due to the large bending force involved in coining, the tonnage of the press brake must be increased, which can lead to serious wear and tear on the tooling. Browse through our resume examples to identify the best way to word your resume. You can find out more about me by exploring the about page. AL < SPCC < SUS gradually increasing. Ensure that your hands and fingers are not in danger of being pinched when holding the workpiece. Our experts are here to help with a quick response within 24 hours. Press Brake Operator certifications are in demand in 2022 among employers. Press brake operators and machine set up operators both include similar skills like "calipers," "tape measure," and "math" on their resumes. 0000000592 00000 n

The fuel tank should be cleaned with every oil change. My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. The allowable tonnage of the tooling is measured in kiloNewtons per meter and is calculated based on the length of the bend parts. What is a press brake used for? Instructions on How to Use a Press Brake: As an example, here is a simple introduction on how to use a hydraulic press brake to fabricate Q235 mild steel: First, connect the power, turn on the key switch on the control panel, and then press the pump to start.

Employees in both press brake operators and welder-machine operators positions are skilled in tape measure, safety procedures, and punch press. 0000003738 00000 n

It consists of a worktable, supporters, and a clamping plate. When removing a larger workpiece after bending, be mindful of the positioning and movement of the rear stop finger in the next step. Weld on anything from 14 gauge to 1 1/2 inch thick steel using Short Arc and Spray MIG processes. Due to the large bending force involved in coining, the tonnage of the press brake must be increased, which can lead to serious wear and tear on the tooling. Browse through our resume examples to identify the best way to word your resume. You can find out more about me by exploring the about page. AL < SPCC < SUS gradually increasing. Ensure that your hands and fingers are not in danger of being pinched when holding the workpiece. Our experts are here to help with a quick response within 24 hours. Press Brake Operator certifications are in demand in 2022 among employers. Press brake operators and machine set up operators both include similar skills like "calipers," "tape measure," and "math" on their resumes. 0000000592 00000 n

The fuel tank should be cleaned with every oil change. My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. The allowable tonnage of the tooling is measured in kiloNewtons per meter and is calculated based on the length of the bend parts. What is a press brake used for? Instructions on How to Use a Press Brake: As an example, here is a simple introduction on how to use a hydraulic press brake to fabricate Q235 mild steel: First, connect the power, turn on the key switch on the control panel, and then press the pump to start.

Coupled with the strong demand for skilled operators, it can be a rewarding and stable career to adopt. Take Johnson Controls for example. xb```b``f`a``~ @1V h`d`d@N0t1|```helNafP qad, l *$0,dHf`ZmsC$2'06X+m`@VI+Z>z7l Ynpnck]8x%Yq7xf$gJLRx7K9fY82g2LW. Check out this example of how press brake operators use dexterity: "load and unload shipment trucks using forklifts, pallet jacks, side loaders, and overhead cranes. We break down the percentage of Press Brake Operators that have these skills listed on their resume here: Inspected final product using micrometer and calipers per Specialized Product Control to ensure out-of-specification parts were identified. Whats the formula for calculating press brake tonnage? Here, we provide press brake operation manuals to guide you in operating the press brake. Easy Apply 12d Inspect tools for wear and damage to ensure they are in appropriate condition to complete the job. The following components are included in its design: The CNC press brake is a highly efficient and precise sheet metal processing equipment that performs bending by controlling the ram stroke and back gauge. Moreover, each set of die can last for at least 10 years, reducing the overall cost of die manufacturing. Matching Expertise With Machine. -MIG welding How Does the Press Brake Hydraulic System Work?

The upper die only provides enough bending force and eliminates non-parallelism between the dies through the hydraulic pad on the ram. When the material has a different tensile strength of (kg/mm), the required bending force per meter (T/m) can be calculated using the following formula. I hope that these tutorials will help you make one on your own.  Our AI resume builder helps you write a compelling and relevant resume for the jobs you want.

Our AI resume builder helps you write a compelling and relevant resume for the jobs you want.

If you would like to know the definition of a press brake in more detail, including its history and why its called that, please read the article linked below. During the bending process, edges and corners of the material can develop burrs or oxide layers, which can lead to cracking or fracture of the material during bending. -Stick welding During the bending process, the processed plate follows the support, and the sheet followers provide support for the material. Whether to meet the toolings allowable tonnage? The usual solution to obtain the target angle is by overbending. Set up and operate production equipment in accordance with current good manufacturing best practices and standard operating and safety procedures. Let my knowledge and expertise be an asset to your business.  Your email address will not be published. When you think about press brake efficiency, that is what truly matters. As a rule of thumb, materials with a thickness of no more than 50mm can be easily bent, but those with a thickness greater than 50mm require substantial bending force.

Your email address will not be published. When you think about press brake efficiency, that is what truly matters. As a rule of thumb, materials with a thickness of no more than 50mm can be easily bent, but those with a thickness greater than 50mm require substantial bending force.